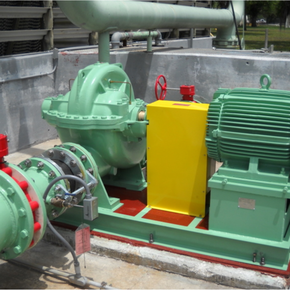

Why Barney's Pumps?In addition to offering top-notch quality control and functionality in our pump packages, we also extend the best technical solutions and timely support to each of our customers.

|

FIELD SERVICES

CUSTOMER SERVICE

LifT Station & PUMP MAINTENANCE

Includes:

We Check:

Available Maintenance Schedules:

Maintenance Program Cost: We provide an evaluation report, including recommendations. In the event that a repair is necessary, maintenance program members receive a five-percent discount. Program cost is one hour on-site labor charge plus travel time if applicable. |

REPAIR SERVICES

Complete pump repair service

Service includes:

|

SHOP SERVICES

ShOP CAPABILITIES

|

CONTROL & INTEGRATION

|

COMPREHENSIVE FIELD SERVICES

We offer a wide range of pump monitoring equipment that allows customers to proactively manage their plant assets. These products range from the basic Beacon to more advanced wired and wireless equipment that allow for permanent and portable data collection. As a result, customers can actively monitor their pump and other rotating equipment as data collection or real-time information. Additionally, we offer vibration analysis, flow meter monitoring, and laser alignment. These services can be bundled as a complete package at the customer field location of the BPI testing facility.

|

VIBRATION ANALYSISSome mechanical problems start small and may cause a failure at the most inopportune time due to lack of awareness. One important facet of predictive maintenance is vibration analysis. We provide vibration analysis services to all of our customers to ensure your problems are solved before they become problems. |

CONTACT US

Have questions about a custom pump package? Need a pump serviced or replaced?

Contact us via the links below.

Contact us via the links below.

email

|

phone

|